Custom CNC machining service

Custom parts manufacturing, from rapid prototyping to on-demand production. Instant quotes and DFM analysis in seconds, quality parts in days.

Our On-Demand CNC machining Services

UTM offers high-precision machining backed by an incredible breadth of manufacturing capabilities. Whether you need prototyping or mass production, our experts utilize advanced technologies to craft products with intricate geometries and superior aesthetics. From complex components to highly-finished parts, we deliver an extensive range of on-demand machining services. Leverage our skilled manufacturing prowess to bring your designs to life with uncompromising quality.

CNC Machining

CNC Milling

CNC Turning

Sheet Metal Fabrication

CNC machining materials

We can generate instant machining quotes for 50+ metals and plastics.

Aluminum is lightweight yet strong, with excellent machinability and corrosion resistance. Ideal for aerospace and automotive parts, our aluminum CNC milling service ensures precise and high-quality machining tailored to your specific needs.

Alloys

Aluminum 6061, 6061-T6

Aluminum 2024

Aluminum 5052

Aluminum 5083

Aluminum 6063

Aluminum 6082

Aluminum 7075, 7075-T6

Aluminum ADC12 (A380)

Copper is known for its superior electrical conductivity and thermal properties, making it perfect for electrical components and heat exchangers.

Alloys

Copper C101(T2)

Copper C103(T1)

Copper C103(TU2)

Copper C110(TU0)

Beryllium Copper

Brass is durable and has a low friction coefficient, which makes it suitable for fittings, tools, and musical instruments that require precision.

Alloys

Brass C27400

Brass C28000

Brass C36000

Bronze is highly resistant to corrosion and metal fatigue, favored for bearings, bushings, and marine hardware.

Alloys

Tin Bronze

View more

Steel is an alloy with high tensile strength and durability, commonly used in construction and automotive industries for its robustness.

Alloys

Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36

Die steel

Alloy steel

Chisel tool steel

Spring steel

High speed steel

Cold rolled steel

Bearing steel

SPCC

View more

Stainless steel is renowned for its corrosion resistance, making it a prime choice for medical devices and food processing equipment.

Alloys

Stainless Steel SUS201

Stainless Steel SUS303

Stainless Steel SUS 304

Stainless Steel SUS316

Stainless Steel SUS316L

Stainless Steel SUS420

Stainless Steel SUS430

Stainless Steel SUS431

Stainless Steel SUS440C

Stainless Steel SUS630/17-4PH

Stainless Steel AISI 304

Magnesium is the lightest structural metal, offering high strength-to-weight ratios, perfect for automotive and aerospace applications where weight is critical.

Alloys

Magnesium Alloy AZ31B

Magnesium Alloy AZ91D

View more

Titanium boasts the highest strength-to-density ratio among metals, highly resistant to corrosion and fatigue, ideal for aerospace, medical, and marine applications.

Alloys

Titanium Alloy TA1

Titanium Alloy TA2

Titanium Alloy TC4/Ti-6Al 4V

ABS is strong, durable, and offers good resistance to heat and impact. It machines easily with smooth surface finishes, preferred for automotive components, consumer goods, and functional prototypes.

ABS Beige(Natural)

ABS Black

ABS Black Antistatic

ABS Milky White

ABS+PC Black

ABS+PC White

Polycarbonate is extremely durable with high impact resistance and clarity, used for bullet-proof glass and protective gear.

PC Black

PC Transparent

PC White

PC Yellowish White

PC+GF30 Black

Acrylic offers excellent optical clarity and light transmission, lighter than glass with superior weather resistance. It’s used for LED diffusers, display cases, and architectural features.

PMMA Black

PMMA Transparent

PMMA White

POM is stiff and dimensionally stable with low friction and excellent machinability. It’s ideal for gears, bearings, and precision mechanical assemblies.

Dark brown (coffee) POM 100AF

POM Black

POM Blue

POM White

Nylon is tough, flexible, and absorbs impact well with excellent abrasion resistance. It’s suitable for wear strips, bushings, and impact-resistant housings.

PA(Nylon) Blue

PA6 (Nylon)+GF15 Black

PA6 (Nylon)+GF30 Black

PA66 (Nylon) Beige(Natural)

PA66 (Nylon) Black

Polyethylene is lightweight and flexible with excellent chemical resistance and impact strength. It’s used for tanks, containers, gaskets, and outdoor applications.

PE Black

PE White

PEEK withstands continuous temperatures up to 480°F and resists nearly all chemicals with exceptional strength. It’s used in aerospace, medical implants, and high-performance industrial applications.

PEEK Beige(Natural)

PEEK Black

Polypropylene provides chemical resistance and fatigue strength at a low cost with FDA approval for food contact. It’s suited for chemical tanks, lab equipment, and living hinges.

PP Black

PP White

PP+GF30 Black

HDPE is lightweight with excellent impact strength, moisture resistance, and chemical resistance. It’s ideal for tanks, containers, and outdoor applications.

HDPE Black

HDPE White

Polystyrene is lightweight and easy to machine with good dimensional stability at low cost. It’s suitable for prototypes, packaging, and low-stress applications.

HIPS Board White

LDPE is flexible and tough with good chemical resistance and low-temperature performance. It’s used for gaskets, seals, and flexible components.

LDPE White

PBT is strong and stiff with excellent dimensional stability and electrical insulation properties. It’s used for electrical connectors, automotive components, and precision housings.

PBT Black

PBT Milky White(Natural)

PPA offers high heat resistance and strength with excellent chemical resistance and dimensional stability. It’s used for automotive under-hood components, electrical connectors, and high-temperature industrial parts.

PAI offers exceptional strength and stiffness with continuous service temperatures up to 500°F and superior wear resistance. It’s used for high-temperature bearings, seals, and aerospace components.

PAI Brown

PET combines clarity, strength, and chemical resistance with FDA approval for food and beverage contact. It’s widely used for packaging, medical devices, and transparent enclosures.

PET Black

PET White

PET+GF30 Black

PET+GF30 White

PPS delivers outstanding chemical resistance and thermal stability up to 400°F with inherent flame retardancy. It’s used for chemical processing equipment, automotive under-hood components, and electrical insulators.

PPS Black

PPS White

PPS+GF30 Black

PPS+GF30 White

PS is lightweight and rigid with good dimensional stability and ease of machining at low cost. It’s suitable for prototypes, packaging, displays, and low-stress applications.

PS Transparent

PVC resists acids and chemicals while remaining cost-effective and easy to machine. It’s commonly used for chemical tanks, piping, and corrosion-resistant equipment.

PVC Grey

PTFE has the lowest coefficient of friction of any solid material and is chemically inert across extreme temperatures. It’s perfect for seals, gaskets, and non-stick applications.

Teflon (PTFE) Black

Teflon (PTFE) White

UPE delivers exceptional abrasion resistance with self-lubricating properties and operates in extreme cold temperatures. It’s ideal for conveyor liners, wear strips, and bulk material handling components.

UPE Black

UPE White

Bakelite is hard and heat-resistant with excellent electrical insulation and dimensional stability under load. It’s used for electrical components, circuit breakers, and high-temperature industrial parts.

Bakelite Black

Bakelite Orange

FR4 is a glass-reinforced epoxy with excellent electrical insulation and mechanical strength across temperature extremes. It’s essential for circuit boards, electrical insulators, and high-voltage applications.

FR-4 Aqua Green

FR-4 Yellow

We can source any other material on request, but quotes take up to 48 hours.

CNC machining surface finishes

We can instantly quote a wide variety of post-machining surface finishes.

As-machined finish retains tool marks and natural surface characteristics from CNC cutting, offering the fastest turnaround and lowest cost.

Polishing achieves a smooth, reflective surface with reduced friction and improved aesthetics, suitable for high-visibility components.

Bead blasting creates uniform matte textures by impacting surfaces with glass beads, producing consistent Ra Ra 0.8–3.2 µm finishes.

Tumbling

Tumbling smooths sharp edges and surfaces through mass finishing, producing consistent deburring and a satin texture for small to medium parts.

Brushing creates directional texture with a brushed-metal aesthetic, commonly used for architectural hardware and consumer electronics.

Powder coating delivers a thick, durable finish with excellent color retention and UV resistance, perfect for outdoor and high-wear applications.

Black oxide forms a dark, corrosion-resistant coating on steel with minimal dimensional change, offering a professional matte-black appearance.

Anodizing increases corrosion resistance and wear properties while allowing for color dyeing, ideal for aluminum parts both protection and aesthetic appeal.

CNC Machining Tolerances

|

Standards

|

CNC Milling

|

CNC Turning

|

|---|---|---|

|

Maximum Part Size |

4000×1500×600 mm |

200×500 mm |

|

Minimum Part Size |

4×4 mm |

2×2 mm |

|

Minimum Feature Size |

Φ 0.50 mm |

Φ 0.50 mm |

|

Standard Tolerances |

Metals: ISO 2768-m |

Metals: ISO 2768-m |

|

Linear Dimension |

+/- 0.005 mm |

+/- 0.005 mm |

|

Hole Diameters |

+/- 0.005 mm |

+/- 0.005 mm |

|

Shaft Diameters |

+/- 0.005 mm |

+/- 0.005 mm |

|

Lead Time |

5 business days |

5 business days |

Overview: What is CNC Machining?

CNC (Computer Numerical Control) machining is an automated manufacturing process that uses high-speed cutting tools to precisely shape metal or plastic stock materials. Common CNC machines include milling machines, lathes, and routers with 3-axis to 5-axis capabilities. The cutting approach varies - the workpiece may be stationary while the tool moves, the tool may be stationary while the workpiece moves, or both may move simultaneously.

Skilled machinists program the tool paths based on CAD models of the final part geometry. CNC machining offers high precision and repeatability, making it suitable for custom parts across industries like aerospace, medical, robotics, and electronics. UTM provides CNC machining services quoting over 40 materials from aluminum to engineered plastics like PEEK and Teflon. The computer control enables automated, efficient material removal through processes like milling, drilling, and turning.

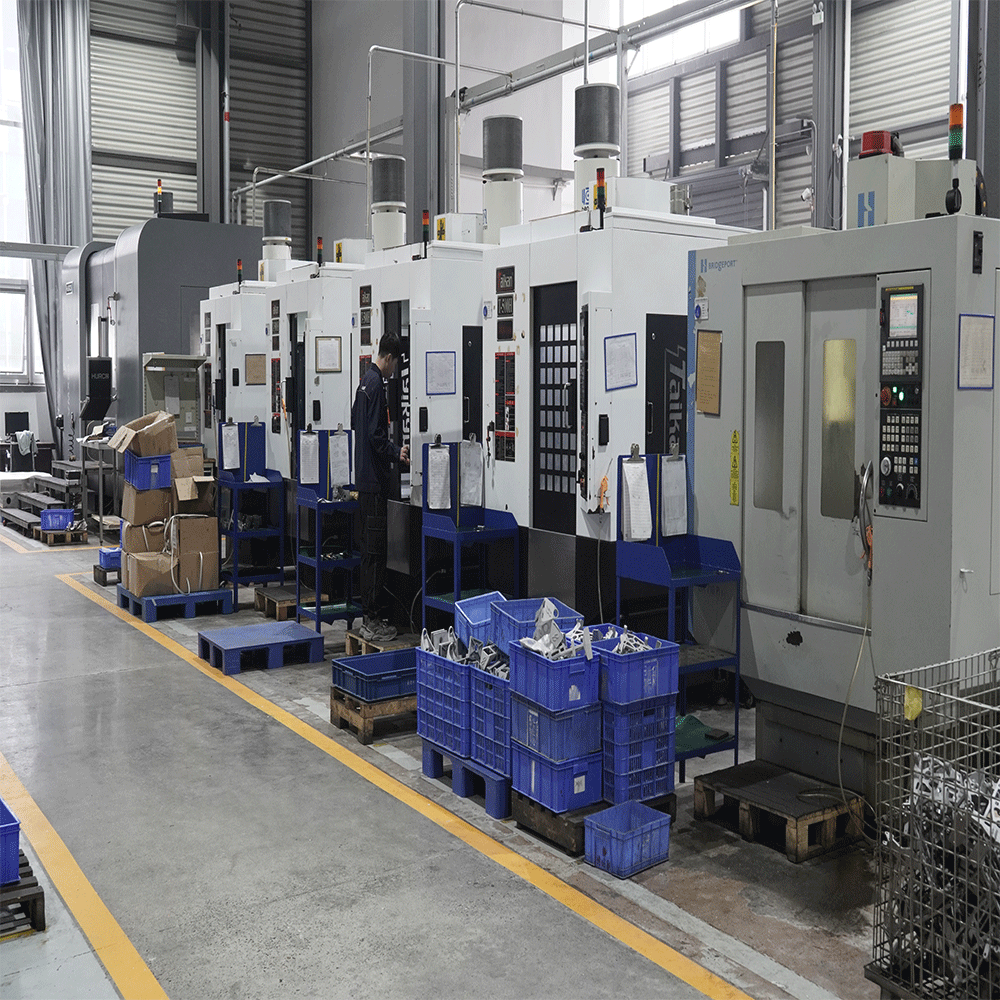

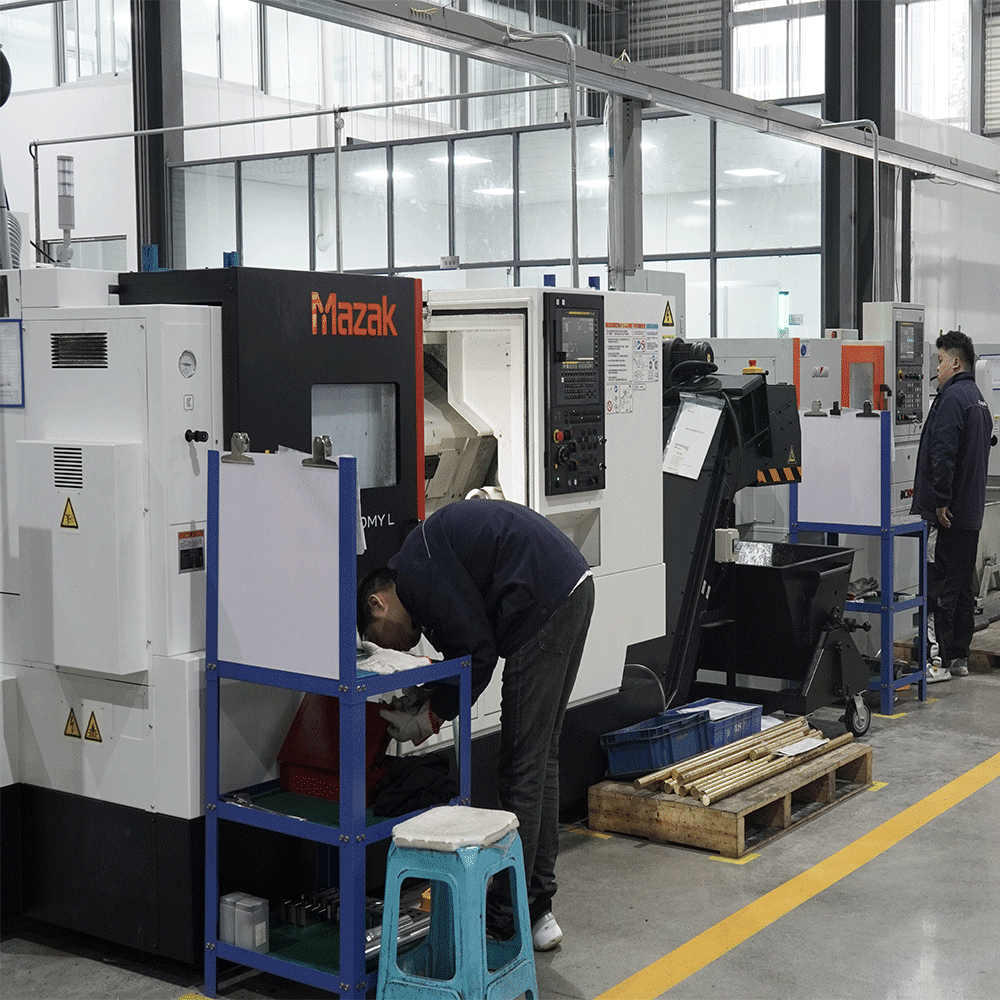

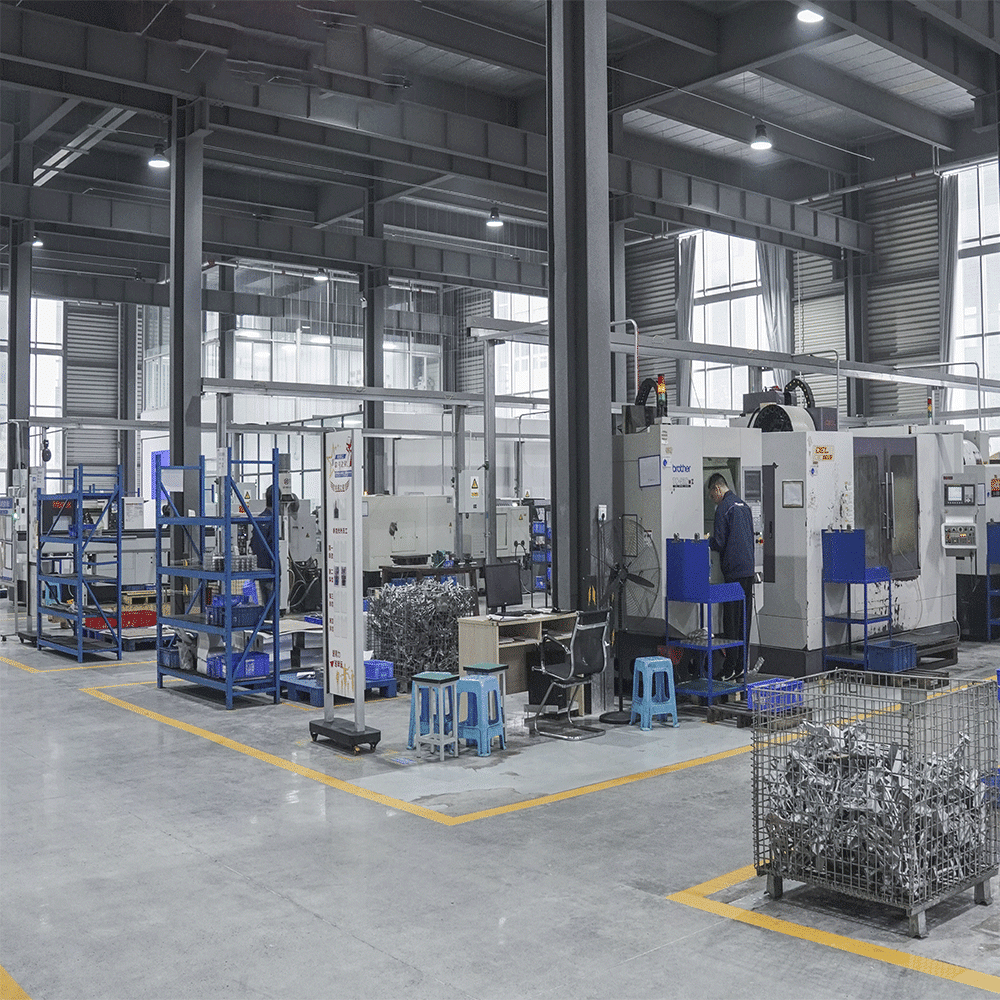

UTM CNC machine shops

About Us

UTM Precision Machining, located in Qingdao China, offers precision CNC milling and turning services for innovative companies around the world. We work with you through every stage of product development and have a team of highly-trained technicians to help you bring your product ideas to life. Whether you need a custom prototype or low-volume production for up to 1000+ units, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time. We’ll go above and beyond to help you bring your product ideas to life!

Why Choose us

Why Choose Us

Manufactured by UTM

How to Order Parts With UTM?

4.Receive your parts

Prototypes and parts will be produced within a few days and delivered directly to you by international express.

Work With Numerous Industries

From prototyping to production, UTM ensures superior quality and reliable functionality. With a wide selection of production-grade metal and plastic materials as well as highly advanced on-demand manufacturing techniques, we offer high-quality products across several industries.

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Medical Devices

Medical supplies manufacturers, tech startups, and research labs benefit significantly from the prototyping solutions we provide.

Consumer Goods

Strong partnerships with leading consumer manufacturers help us accelerate the prototyping process and improve the consumer goods industry.

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

Industrial machinery

Multiple material choices make industrial parts more competitive.

Quality Services

Clients Love

UTM is an extremely professional company with great customer service. Everything we ordered arrived as expected. There were some initial problems, but Kobe helped find a solution that worked for both sides. We will definitely use them again.

UrbanFor my last order, the customer support was amazing. Kobe helped me solve a logistics issue and the algo parts were excellent quality as expected. I'm super happy with the support and service. For my next order, I'll be increasing the number of parts since I know the quality and service will be great.

Andres CI ordered 50 CNC machined stainless steel parts and they turned out great. The dimensions were right on and the parts were clean and smooth. I'll definitely order from them again.

Wim Peter

They do what they say they'll do. Sometimes they even finish sooner than promised. If we have any problems or questions, they always give us helpful answers. You can count on them.

Wim