Brushing Finish Services

Achieve Superior Matte Finishes with Professional Brushed Finishing – Custom Linear and Circular Grain Patterns for Metal Parts

Brushing Finish Surface Finish Specifications

| Applicable Materials | Grit/Grain | Glossiness | Visual Appearance |

|---|---|---|---|

| Aluminum, Zinc, Titanium, Steel, Stainless steel, Bronze, Brass, Copper | #120, #150, #180, #200, #220 | Unidirectional satin finish | Introduces a textured appearance while helping to hide fingerprints and minor imperfections. |

Brushing Finish Service Overview

Brushed finishing is a surface finish process involving the mechanical polishing of metal surfaces using wire brushes or abrasive pads to create a distinctive texture in a specific direction.

During the brushing process, the wire brush or abrasive pad removes a thin layer of the metal surface, creating a matte appearance with fine lines (grain), which can be linear or circular. This controlled abrasion produces a uniform directional pattern that enhances both aesthetics and functionality.

Brushed finishing services work with different materials, the commonest being stainless steel, aluminum, brass, and bronze. Aside from being visually appealing, the brushed metal finish is resistant to scratches and fingerprints, making it ideal for high-touch applications and environments requiring easy maintenance.

Brushing Finish Advantages

Advantages

Important Notes

Custom Brushing Finish Part Made Simple

Our ordering process

Request for quote

Share project details for competitive pricing

Quote and design analysis

Detailed quote with design evaluation

Production

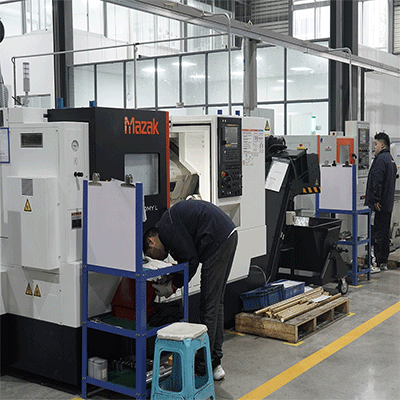

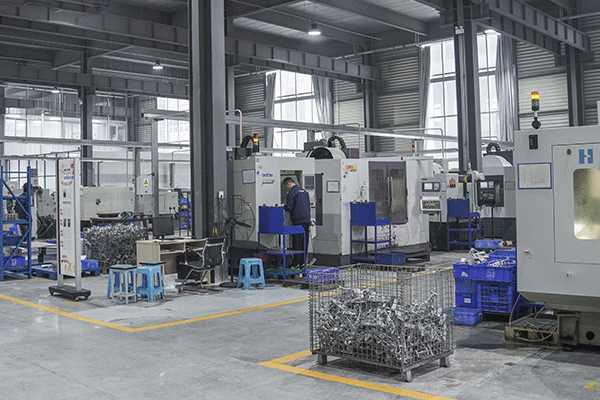

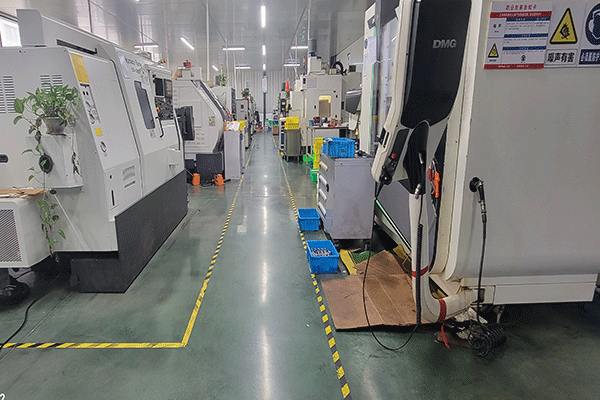

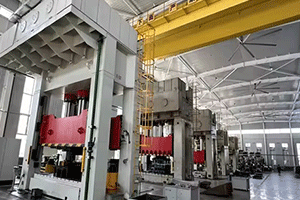

Precision manufacturing with advanced CNC systems

Quality control

Rigorous inspections ensure specifications

Delivery

Reliable shipping worldwide

About Us

Since 2012, we've been at the forefront of CNC machining, initially specializing in manufacturing precision molds and evolving to provide comprehensive in-house production of machined parts. This journey has allowed us to complete over 1270 custom projects, equipping us with extensive experience in overcoming diverse machining challenges. We continuously refine our techniques, ensuring optimal quality for every component.

Our Commitment to Your Success:

-

17+ Years of Expertise: Our deep specialization in machining production across various industries enables efficient problem-solving and innovation.

-

Self-Owned Workshop: Our in-house machining facility significantly shortens production cycles and reduces your procurement costs by at least 10%.

-

Unwavering Confidentiality: We prioritize the utmost confidentiality for your designs and intellectual property, always signing protection agreements.

-

Real-Time Order Tracking: Stay informed with continuous production updates throughout your order's journey.

Factory Photo

Frequently Asked Questions (FAQs)

What's the difference between linear and circular brushed finishes?

Linear brushing creates parallel grain lines in one direction (common for architectural panels), while circular brushing produces concentric rings (ideal for cookware and decorative items). We can customize the pattern orientation to your design specifications.

What materials can be brushed?

We process all common metals including aluminum, stainless steel, carbon steel, titanium, brass, bronze, and copper. Specialty alloys like Inconel and cobalt-chrome can also be brushed with proper process parameters.

Can you match existing finish samples?

Yes. Send us your reference sample and we’ll analyze the finish using profilometry to measure Ra values. We then reverse-engineer the parameters and produce trial pieces for your approval.

Can you brush parts after welding?

Yes. Brushing is commonly performed after welding to clean weld discoloration, blend weld beads with base metal, and create uniform appearance. For stainless steel, passivation after brushing restores corrosion resistance.