Stainless Steel CNC Machining Service

Precision CNC machined stainless steel parts are preferred by many industries due to stainless steel's desirable physical properties and the accuracy of CNC machining.

Our Stainless Steel CNC Machining Material Choice

We machine eight premium stainless steel alloys—from versatile 304/304L to marine-grade 316/316L and high-strength 17-4 PH—each optimized for specific performance requirements. From food-grade applications to aerospace components, find the perfect stainless steel grade for your project.

Stainless steel 304 is the most common stainless steel. It is essentially non-magnetic and less electrically and thermally conductive than carbon steel. The “L” grade has lower carbon content (0.03% max), improving weldability.

Key Properties:

- Excellent corrosion resistance in atmospheric conditions

- Non-magnetic in annealed condition

- Superb formability and weldability

- Low thermal conductivity (16.2 W/m·K at 100°C)

- Low electrical conductivity compared to carbon steel

- Tensile strength: 75,000 psi (515 MPa)

- Operating temperature range: -196°C to 800°C

- Superior corrosion resistance, especially against chlorides and acids

- Excellent resistance to pitting and crevice corrosion

- Non-magnetic

- Higher creep and stress-rupture strength at elevated temperatures

- Tensile strength: 85,000 psi (585 MPa)

- Maintains ductility at cryogenic temperatures down to -196°C

Key Properties:

- Tensile Strength: 572 MPa (83,000 psi)

- Yield Strength: 503 MPa (73,000 psi)

- Elongation at Break: 11%

- Hardness: 150 Brinell

- Density: 2.81 g/cm³ (0.101 lb/in³)

Stainless steel 303 is an austenitic chromium-nickel steel with added sulfur for superior machinability. It is non-magnetic in the annealed condition and offers excellent toughness with slightly lower corrosion resistance than 304.

Key Properties:

- Excellent machinability (best in 300 series)

- Good corrosion resistance in mild environments

- Non-magnetic

- High tensile strength: 90,000 psi (620 MPa)

- Hardness: 85 HRB

- Good at elevated temperatures up to 425°C

Aluminum 2024 is a high-strength copper-based alloy used extensively in the aviation industry. It offers excellent fatigue resistance and fracture toughness, making it ideal for structural components subjected to repeated stress cycles. While not weldable (riveting is preferred), 2024 delivers superior performance in applications where fatigue life is critical.

Key Properties:

- Tensile Strength: 483 MPa (70,000 psi)

- Yield Strength: 345 MPa (50,000 psi)

- Elongation at Break: 18%

- Hardness: 120 Brinell

- Density: 2.78 g/cm³ (0.100 lb/in³)

Stainless steel 17-4 PH is a precipitation-hardening martensitic alloy with 17% chromium and 4% nickel. It is magnetic and can be age-hardened to significantly higher strengths than austenitic stainless steels.

Key Properties:

- High strength after heat treatment: up to 200,000 psi (1380 MPa)

- Hardenable to 44 HRC through aging at 480-620°C

- Good corrosion resistance comparable to 304

- Magnetic

- Excellent toughness and ductility

- Usable at temperatures up to 315°C

Our Stainless Steel CNC Machining Surface Finishing Choice

We offer complete finishing capabilities—from as-machined and bead blasting to passivation and electropolishing—each delivering specific functional or aesthetic properties. From enhanced corrosion protection to pharmaceutical-grade surface finish, find the perfect finish for your stainless steel parts.

As Machined

This is the default finish directly from the CNC machine. Tool paths and marks are visible. It’s ideal for functional or internal components where appearance isn’t a priority. Cost-effective and fast, this finish is often used for prototypes and parts not requiring surface refinement.

Bead Blasting

Bead blasting creates a uniform matte texture by propelling fine glass beads at the aluminum surface. This process removes tool marks and produces a consistent, non-reflective appearance across the entire part. It’s commonly used when parts require a professional look without the cost of anodizing.

Tumbling Finish

Tumbling smooths sharp edges and burrs through mechanical abrasion in a vibratory bowl. Parts tumble with ceramic media, creating a soft, consistent finish while rounding corners and improving surface uniformity. This process works well for small to medium-sized parts requiring edge break and aesthetic improvement.

Polishing

Polishing produces a smooth, reflective surface through progressive abrasive techniques. This finish ranges from semi-bright to mirror-like depending on the level of polishing applied. It’s ideal for decorative applications, optical components, or parts requiring minimal surface roughness for functional reasons.

Anodizing Type II (DECORATIVE)

Anodizing Type II grows a controlled oxide layer on the aluminum surface through an electrochemical process. This layer provides corrosion protection and accepts dyes for color options including clear, black, red, blue, and gold. The coating thickness ranges from 0.0002″ to 0.001″ and integrates into the aluminum structure rather than sitting on top.

Anodizing Type III HARDCOAT

Anodizing Type III creates a thicker, harder oxide layer than Type II, significantly improving wear resistance and durability. This process typically produces a black or natural gray finish and is commonly specified for parts subjected to abrasion or harsh environments. The coating thickness ranges from 0.001″ to 0.004″.

Alodine/Chromat

Alodine (chromate conversion coating) provides corrosion protection while maintaining electrical conductivity. This thin chemical coating appears clear or gold and serves as an excellent base for paint or as a standalone protective finish. It’s commonly used in aerospace and military applications where conductivity must be preserved.

Powder Coating

Powder coating applies dry powder electrostatically, then cures it under heat to form a durable, uniform finish. This process offers unlimited color options, excellent impact resistance, and superior corrosion protection. The coating thickness typically ranges from 0.002″ to 0.010″ and provides both aesthetic appeal and functional protection.

Electroless Nickel Plating

Electroless nickel plating deposits a uniform nickel-phosphorus coating through chemical reduction rather than electrical current. This process provides exceptional corrosion resistance, wear protection, and consistent coverage even in complex geometries and internal passages. The coating appears semi-bright gray and offers excellent lubricity.

Laser Marking

Laser marking permanently marks aluminum surfaces with text, logos, serial numbers, or 2D barcodes without adding material or changing dimensions. This non-contact process creates high-contrast marks that resist wear and environmental exposure. It’s ideal for traceability requirements and branding applications where permanent identification is essential.

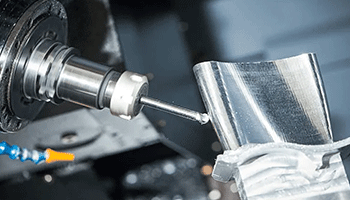

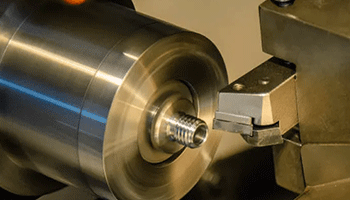

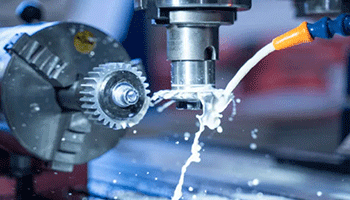

Our Stainless Steel CNC Machining Services Capabilities

Complete CNC machining services including precision milling (3-axis, 4-axis, 5-axis) and turning with tolerances to ±0.0005″. From simple brackets to complex medical implants with tight tolerances and superior surface finishes.

CNC Machining Service

CNC Turning Service

CNC Milling Service

Industries And Applications Of Precision CNC Machined Stainless Steel Parts

Trusted stainless steel machining partner across aerospace, medical devices, food & beverage, marine, chemical processing, and oil & gas sectors. Delivering critical components that meet the most demanding specifications in each industry.

Aerospace & Defense

Stainless steel components in aerospace applications demand exceptional reliability and precise performance under extreme conditions. Our AS9100 certified manufacturing ensures every part meets stringent aerospace quality standards.

Medical Devices

Medical applications require exceptional precision, complete traceability, and compliance with rigorous regulatory standards. Our ISO 13485 certified processes support life-saving medical equipment through reliable performance and consistent quality.

Food & Beverage Processing

The food industry requires FDA-compliant materials with superior corrosion resistance and easy sterilization. We produce food-grade stainless steel components that maintain hygiene standards while withstanding harsh cleaning protocols.

Marine & Coastal Applications

Marine environments demand materials that resist saltwater corrosion and maintain structural integrity. Our 316/316L machining capabilities deliver components that perform reliably in the harshest coastal and offshore conditions.

Why Choose Us for Your Copper CNC Machining Needs?

Rapid Prototyping Available

Need it fast? Our 3–5 day rapid prototyping service gets functional prototypes in your hands quickly for testing and validation.

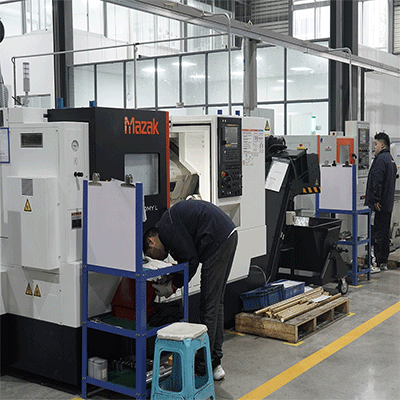

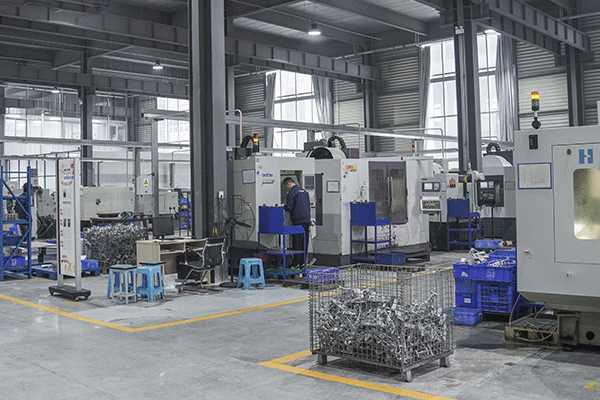

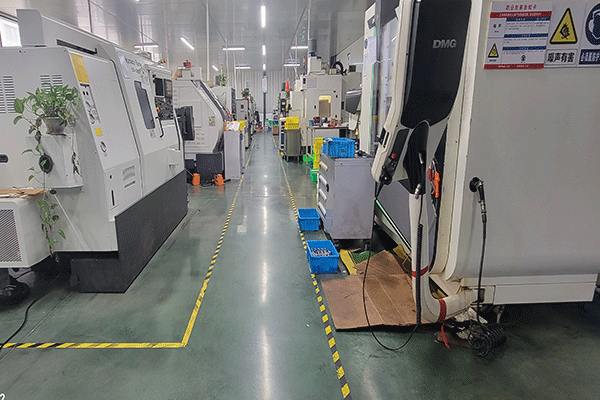

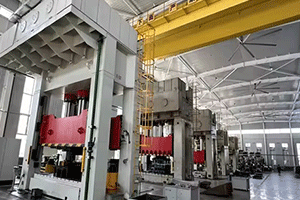

Complete In-House Manufacturing

50+ CNC machines under one roof means faster turnaround, better quality control, and no outsourcing delays. You work directly with the people making your parts.

No Minimum Order Quantity

From 1 prototype to 10,000 production parts, we provide the same precision and care. Perfect for startups, R&D teams, and established manufacturers alike.

Full CMM Inspection Included

Every order includes dimensional verification using Coordinate Measuring Machines. First article inspection reports (FAIR) available at no extra charge.

Custom CNC Stainless Steel Parts Made Simple

Get 10-day standard lead times on custom stainless steel components. Upload your drawings to see how we can deliver precision for your application.

Our ordering process

Request for quote

Share project details for competitive pricing

Quote and design analysis

Detailed quote with design evaluation

Production

Precision manufacturing with advanced CNC systems

Quality control

Rigorous inspections ensure specifications

Delivery

Reliable shipping worldwide

About Us

Since 2012, we've been at the forefront of CNC machining, initially specializing in manufacturing precision molds and evolving to provide comprehensive in-house production of machined parts. This journey has allowed us to complete over 1270 custom projects, equipping us with extensive experience in overcoming diverse machining challenges. We continuously refine our techniques, ensuring optimal quality for every component.

Our Commitment to Your Success:

-

17+ Years of Expertise: Our deep specialization in machining production across various industries enables efficient problem-solving and innovation.

-

Self-Owned Workshop: Our in-house machining facility significantly shortens production cycles and reduces your procurement costs by at least 10%.

-

Unwavering Confidentiality: We prioritize the utmost confidentiality for your designs and intellectual property, always signing protection agreements.

-

Real-Time Order Tracking: Stay informed with continuous production updates throughout your order's journey.

Factory Photo

Stainless Steel CNC Machining Frequently Asked Questions (FAQs)

What aluminum alloy should I choose for my part?

The right aluminum alloy depends on your specific application requirements.

- Aluminum 6061-T6 – Most versatile for general purpose, good strength and machinability

- Aluminum 7075-T6 – Maximum strength for high-stress aerospace applications

- Aluminum 5052 – Superior corrosion resistance for marine environments

- Aluminum 2024-T3 – Excellent fatigue resistance for repeated stress cycles

- Aluminum MIC-6 – Exceptional flatness for precision tooling and fixtures

Our engineering team can recommend the optimal alloy for your application.

How long does custom CNC machining take?

- Rapid Prototyping: 3-5 business days

- Standard Production: 10-15 business days

- High-Volume Production: 3-4 weeks

Can you machine complex geometries and undercuts?

Five-axis CNC machining handles deep pockets, compound curves, and features on multiple faces in single setups.

Internal undercuts may require specialized tooling, EDM, or design modifications. Upload your CAD file for manufacturability assessment.

Do You Offer Finishing Services for Brass Parts?

Yes. We provide complete brass finishing including deburring, polishing, plating (nickel, chrome, tin, silver, gold), powder coating, passivation, and custom finishes.

Why does aluminum offer advantages for CNC machining?

Aluminum offers specific benefits that simplify and improve the process of CNC machining. Many grades of aluminum can be effectively penetrated with cutting tools. Aluminum will chip easily and is relatively easy to shape, making aluminum three times faster to machine than iron or steel.

Other benefits include:

- Machinability

- Corrosion resistance

- Strength-to-weight ratio

- Electrical conductivity

- Anodization potential

- Recyclability