Custom Brass CNC Machining Service

Expert brass machining for prototypes and production runs. No minimum order quantity. Engineering support included with every quote.

Our Brass CNC Machining Service Material Choice

At UTM, our Brass CNC Machining Service is designed to meet your needs at every stage, from one-off functional prototypes to small-batch production for market testing or full-scale manufacturing. We offer CNC machining services for a wide range of brass materials, including C360.C260,C464C,C230. If your project requires a specific brass grade, we are fully capable of sourcing and machining according to your custom specifications.

Brass C360 is the most machinable brass alloy available, containing approximately 61% copper, 36% zinc, and 3% lead. This composition creates exceptional machinability, allowing for high-speed CNC operations, excellent chip formation, and superior surface finishes with minimal tool wear—ideal for high-volume production and complex geometries.

Key Properties:

- Tensile Strength: 124-310 MPa (18,000-45,000 psi)

- Yield Strength: 55-170 MPa (8,000-25,000 psi)

- Elongation at Break: 30-53%

- Hardness (Brinell): 63-130

- Density: 8.49 g/cm³ (0.307 lb/in³)

- Maximum Service Temp: 200°C (392°F)

Best For: Gears, valves, screw machine parts, fittings, electrical connectors, high-volume production components

Cartridge Brass C260, also known as 70/30 brass, contains approximately 70% copper and 30% zinc. This high-copper content provides excellent electrical conductivity, superior formability, and attractive golden color—making it ideal for both functional and decorative applications.

Key Properties:

- Tensile Strength: 427 MPa (62,000 psi)

- Yield Strength: 358 MPa (52,000 psi)

- Elongation at Break: 23%

- Hardness (Brinell): 60

- Shear Modulus: 40 GPa

- Density: 8.53 g/cm³ (0.308 lb/in³)

- Maximum Service Temp: 915-955°C (1,680-1,750°F)

Best For: Radiator cores, lighting fixtures, plumbing components, electrical terminals, ammunition components, architectural trim.

Naval Brass C464 contains approximately 60% copper, 39% zinc, and 0.75% tin, specifically engineered for marine applications. The tin addition provides exceptional resistance to saltwater corrosion and dezincification, making it the material of choice for demanding marine environments.

Key Properties:

- Tensile Strength: 380-520 MPa (55,000-75,000 psi)

- Yield Strength: 170-350 MPa

- Hardness (Brinell): 75-105

- Corrosion Resistance: Excellent in seawater

- Dezincification Resistance: Superior

Best For: Marine hardware, pump components, valve bodies, offshore equipment, saltwater applications

Brass C230, consisting of approximately 85% copper and 15% zinc, sits at the high-copper end of the brass alloy spectrum. This composition delivers enhanced electrical and thermal conductivity along with the distinctive reddish-gold color that gives the alloy its name. When appearance, conductivity, or corrosion resistance takes priority over easy machinability, red brass provides excellent performance.

Key Properties of C230 Red Brass:

- Tensile Strength: 275-540 MPa

- Yield Strength: 70-380 MPa

- Elongation at Break: 5-55%

- Hardness: 50-135 Brinell

- Density: 8.75 g/cm³

- Thermal Conductivity: 159 W/m·K

- Electrical Conductivity: 44% IACS

- Corrosion Resistance: Excellent

Surface Finishing Options for CNC Machining Brass

Brass CNC machining Service can benefit from various finishing techniques to improve corrosion resistance, visual appeal, electrical insulation, or surface hardness. Below are common options:

As Machined Brass Finish

This is the default finish directly from the CNC machine. Tool paths and marks are visible. It’s ideal for functional or internal components where appearance isn’t a priority. Cost-effective and fast, this finish is often used for prototypes and parts not requiring surface refinement.

Sand Blasting for Brass Parts

Sand or other abrasives are sprayed at high speed to create a uniform matte or satin texture. This process effectively removes surface imperfections and provides a consistent base for further coatings like painting or anodizing.

Brass Tumbling Finish

Also known as barrel finishing, this method involves placing parts in a drum with abrasive media. As the drum rotates, it smooths and deburrs the surface. Tumbling is commonly used for small brass parts to achieve a semi-polished or even satin-like finish.

Electropolishing for Brass

This electrochemical process removes a thin layer of the metal surface, reducing roughness and enhancing brightness. It also improves corrosion resistance and is particularly beneficial for complex or small components that are difficult to polish mechanically.

Alodine Finish for Brass Parts

We accept STEP, IGES, SolidWorks, Inventor, Fusion 360, CATIA, and other CAD formats. 2D drawings in PDF or DWG also accepted.

Electroless Nickel Plating on Brass

A chemical plating technique that coats brass with a uniform layer of nickel, enhancing hardness, corrosion resistance, and wear properties. Unlike traditional electroplating, it doesn’t require electricity, making it ideal for parts with complex geometries.

Painting for Brass Components

A versatile finishing method that adds color, UV protection, and surface sealing. Various paint types can be applied depending on the part’s environment and purpose, ranging from decorative to functional coatings.

Powder Coating for Brass Parts

A durable, protective finish where powder is electrostatically applied and then cured under heat. It offers excellent abrasion and weather resistance and is available in a wide variety of colors, sheens, and textures.

Electrophoresis Coating

This method uses an electric field to deposit a uniform, corrosion-resistant film over brass parts. It is ideal for coating intricate shapes and internal surfaces and can be used in combination with powder coating or paint for enhanced durability.

Brushed Brass Finish

A linear pattern is created on the surface using brushes or abrasive belts. The resulting texture gives a clean, satin appearance. It’s commonly found in high-end electronics, appliances, and decorative parts due to its modern and premium look.

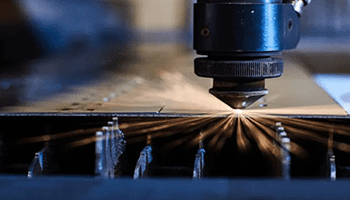

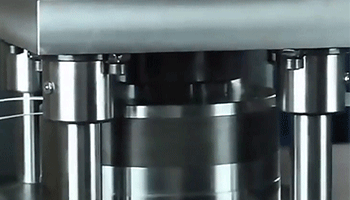

Our Brass CNC Machining Services Capabilities

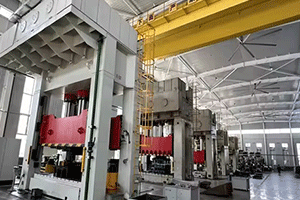

UTM specializes in precision parts processing, non-standard parts custom processing, die casting, stamping, sheet metal and tooling, fixture, customization, and assembly services. We focus on client’s demands and client’s satisfaction

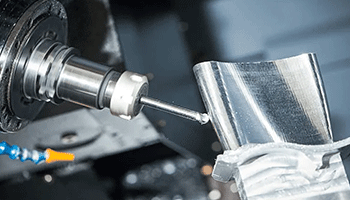

CNC Machining Service

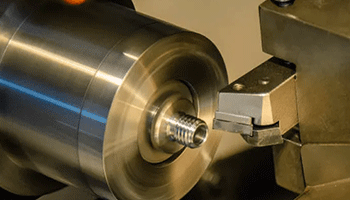

CNC Turning Service

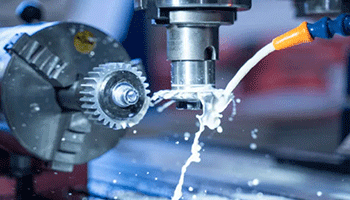

CNC Milling Service

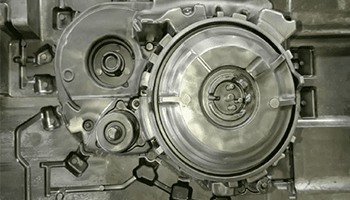

Die Casting Service

Sheet Metal Fabrication

Metal Stamping Service

Applications of CNC Machined Brass Parts Across Industries

Brass is widely used across industries due to its durability, machinability, and attractive appearance. CNC machining enhances its precision for a variety of applications, including:

Electrical Components

Plug connectors, battery terminals, switches, automotive terminals, and electrical housings

Plumbing and HVAC Brass Parts

Pipe fittings, water valves, hose nozzles, manifolds, and other plumbing parts

Automotive Brass Components

Radiator cores, electrical connectors, bushings, threaded parts, and fuel system components

Marine Brass Hardware

Propellers, fittings, ship hardware, valve bodies, and corrosion-resistant fasteners

Decorative Brass Items

Door handles, knobs, rings, bracelets, jewelry, and architectural trim

Mechanical Brass Parts

Gears, nuts, screw threads, bearing rings, clock hands, and precision instruments

Advantages and Disadvantages of Brass CNC Machining

Brass is a widely used material in CNC machining due to its excellent machinability, corrosion resistance, and aesthetic appearance. However, like any material, it comes with both benefits and limitations.

| ✅ Advantages | ❌ Disadvantages |

|---|---|

|

Excellent Machinability Fast cutting speeds, low tool wear, reduced manufacturing costs |

Lower Strength Than Steel Not ideal for heavy-load structural parts |

|

Corrosion Resistant Performs well in humid and marine environments without degradation |

Limited Environmental Suitability Can tarnish without protective coating in certain environments |

|

Great Surface Finish Naturally smooth finish, minimal post-processing needed |

Higher Material Cost More expensive than aluminum or plastics |

|

High Electrical Conductivity Perfect for electronic and electrical applications |

Contains Lead in Some Grades May not meet RoHS compliance for certain industries |

|

Precision Friendly Achieves tight tolerances (±0.005mm) consistently |

Soft Material Scratches easier during handling and assembly |

|

Attractive Appearance Golden color suitable for decorative applications |

|

|

Antimicrobial Properties Natural bacteria resistance for medical and food contact |

About Us

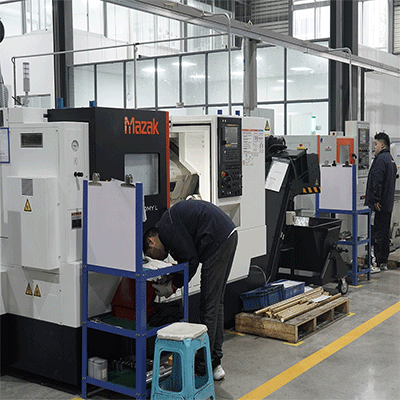

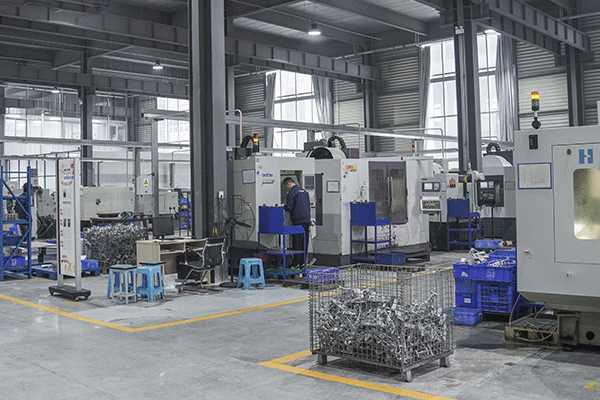

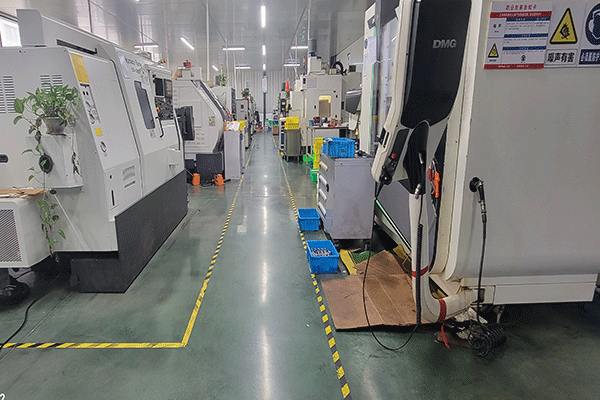

Since 2012, we've been at the forefront of CNC machining, initially specializing in manufacturing precision molds and evolving to provide comprehensive in-house production of machined parts. This journey has allowed us to complete over 1270 custom projects, equipping us with extensive experience in overcoming diverse machining challenges. We continuously refine our techniques, ensuring optimal quality for every component.

Our Commitment to Your Success:

-

17+ Years of Expertise: Our deep specialization in machining production across various industries enables efficient problem-solving and innovation.

-

Self-Owned Workshop: Our in-house machining facility significantly shortens production cycles and reduces your procurement costs by at least 10%.

-

Unwavering Confidentiality: We prioritize the utmost confidentiality for your designs and intellectual property, always signing protection agreements.

-

Real-Time Order Tracking: Stay informed with continuous production updates throughout your order's journey.

Factory Photo

Brass CNC Machining Frequently Asked Questions (FAQs)

What is the Minimum Order Quantity for Brass Parts?

No minimum order quantity for brass machining. We handle single prototypes through mass production runs of 100,000+ pieces.

How Fast Can You Deliver CNC Machined Brass Parts?

Simple brass parts ship in as fast as 3 days. Standard lead time is 7-10 business days for complex brass components. Expedited brass machining services available.

What Brass Alloys Do You Machine?

We machine 10+ brass alloys including Free-Cutting Brass C360, Cartridge Brass C260, Naval Brass C464, Admiralty Brass C443, Architectural Bronze C385, and others. Not sure which brass alloy is right? We provide free material consultation.

Do You Offer Finishing Services for Brass Parts?

Yes. We provide complete brass finishing including deburring, polishing, plating (nickel, chrome, tin, silver, gold), powder coating, passivation, and custom finishes.

What File Formats Do You Accept for Brass Part Quotes?

We accept STEP, IGES, SolidWorks, Inventor, Fusion 360, CATIA, and other CAD formats. 2D drawings in PDF or DWG also accepted.