Direct Factory Price

China Top Precision CNC Machining Service Manufacturer

Save At Least 10% on Your Procurement Costs

No MOQ – Small Orders Welcome

Fast Delivery: 3–25 Days

Experienced Auto Parts Manufacturer

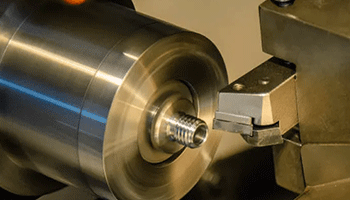

Precision turned parts Manufacturer

Precision milled parts Manufacturer

Let's Talk About Your Project!

10%

Save Cost

1270+

PROJECTS COMPLETED

17+

YEARS OF EXPERIENCE

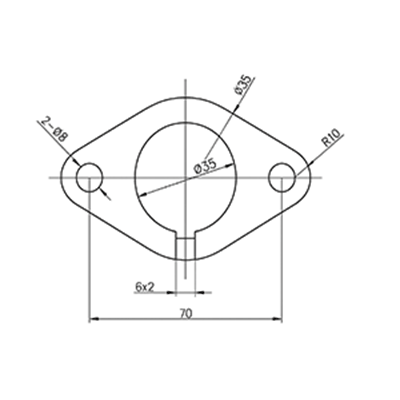

Custom Your Machined Part

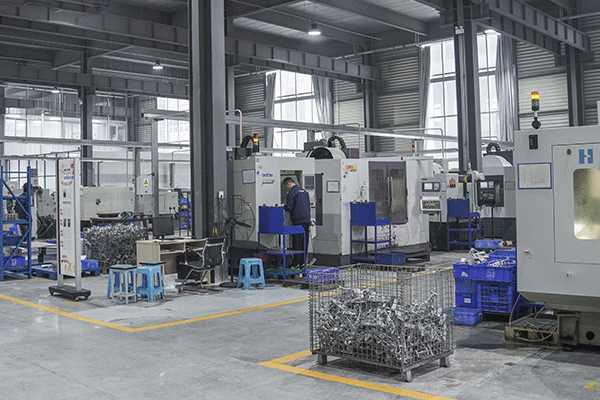

As a leading CNC machining part manufacturer, we offer a seamless, end-to-end production process. Our state-of-the-art facility and team of expert machinists ensure every part is crafted to your exact specifications.

STEP 1: Consultation & Design

We start by reviewing your design and optimizing it for cost and performance.

STEP 2: Program & Prototyping

After a final design, we create a program and produce a prototype for your approval.

STEP 3: Production

Once you approve the prototype, we begin high-volume production with integrated quality checks to ensure consistent quality.

STEP 4: Finishing & Assembly

We perform all required finishing, surface treatments, or assembly on your parts.

STEP 5: Final Quality Control

Before dispatch, we perform a rigorous final quality inspection on every part to guarantee accuracy.

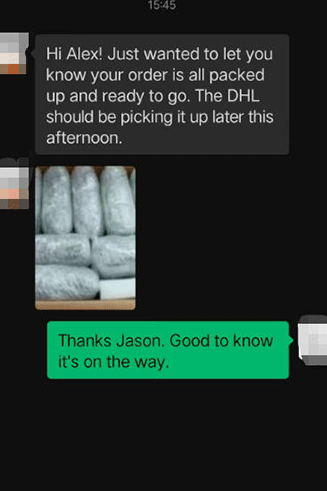

STEP 6: Packaging & Dispatch

Your completed parts are securely packaged and promptly dispatched for delivery.

Our Solution to Your Machining Problems

We don’t guess on quality—we guarantee it. With over 17 years of experience and 1270+ projects completed, our expertise ensures your parts are engineered for performance.

Tired of costly rework?

We eliminate dimensional errors from the start, using advanced inspection tools like coordinate-measuring machines (CMMs) and 3D optical blue light scanners to guarantee every product meets your exact specifications.

Frustrated by miscommunication?

We provide robust support post-delivery, addressing any performance or quality concerns quickly and professionally. Our goal is to be your long-term partner.

Worried about after-sales support?

We provide robust support post-delivery, addressing any performance or quality concerns quickly and professionally.

Need a partner for your toughest projects?

After finishing and assembly, we perform a rigorous final quality control inspection on every batch.

Our CNC Machining Service Capabilities

UTM specializes in precision parts processing, non-standard parts custom processing, die casting, stamping, sheet metal and tooling, fixture, customization, and assembly services. We focus on client’s demands and client’s satisfaction

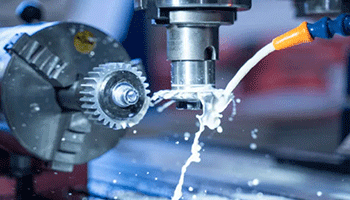

CNC Machining Service

CNC旋盤サービス

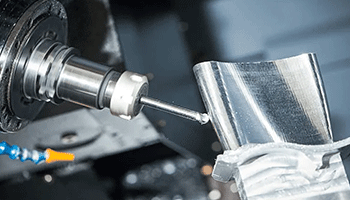

CNC Milling Service

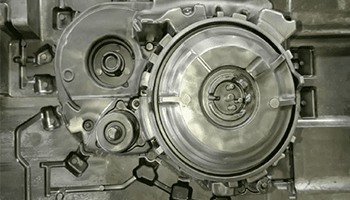

Die Casting Service

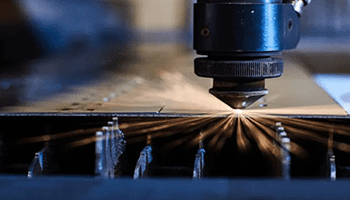

板金加工

Metal Stamping Service

Why Choose Us?

Cost Reduction

Our in-house workshop and advanced CNC machines reduce production cycles and guarantee a 10% cost reduction. We can achieve tolerances as low as ±0.005mm.

Specialized Multi-Axis Expertise

We manage end-to-end multi-axis machining projects, from CAD model to final part, ensuring your project meets exact specifications and complex geometries are handled with ease.

Pinpoint Quality Control

Our advanced 3D optical blue light scanning system verifies every part with micron-level accuracy, ensuring flawless quality and performance.

Transparency & Confidentiality

We provide real-time project updates and sign non-disclosure agreements (NDAs) for every project, keeping you informed and your designs secure.

About Us

Since 2012, we've been at the forefront of CNC machining, initially specializing in manufacturing precision molds and evolving to provide comprehensive in-house production of machined parts. This journey has allowed us to complete over 1270 custom projects, equipping us with extensive experience in overcoming diverse machining challenges. We continuously refine our techniques, ensuring optimal quality for every component.

Our Commitment to Your Success:

-

17+ Years of Expertise: Our deep specialization in machining production across various industries enables efficient problem-solving and innovation.

-

Self-Owned Workshop: Our in-house machining facility significantly shortens production cycles and reduces your procurement costs by at least 10%.

-

Unwavering Confidentiality: We prioritize the utmost confidentiality for your designs and intellectual property, always signing protection agreements.

-

Real-Time Order Tracking: Stay informed with continuous production updates throughout your order's journey.

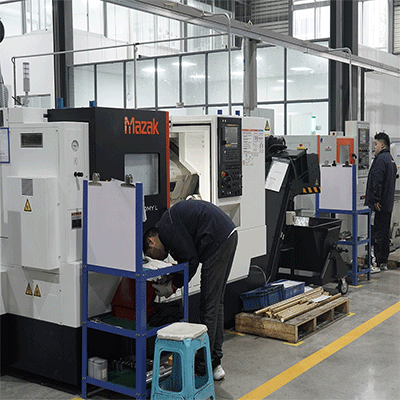

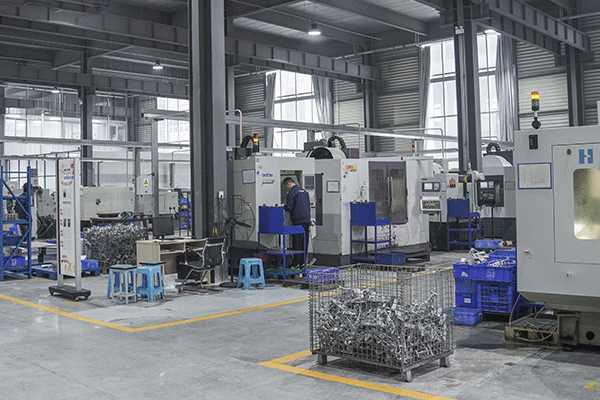

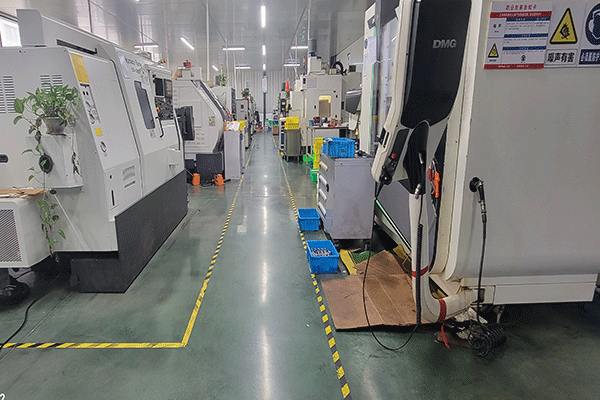

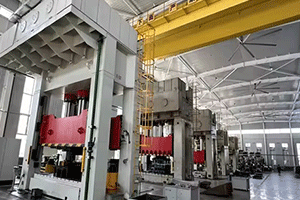

Factory Photo

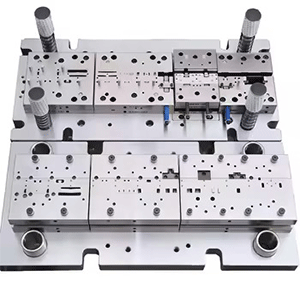

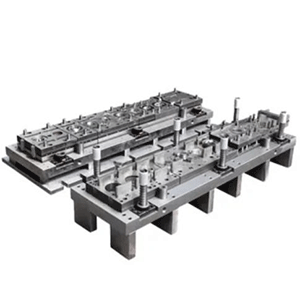

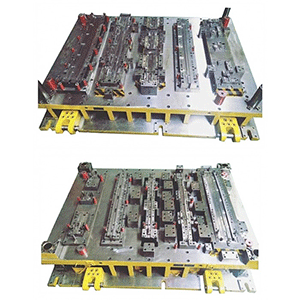

Our Dedicated Die Workshop

Benefit from streamlined production and lower costs with our self-owned metal stamping die manufacturing facility. Our dedicated team and advanced workshop enable us to produce all stamping dies in-house, significantly reducing your product costs and accelerating production lead times.

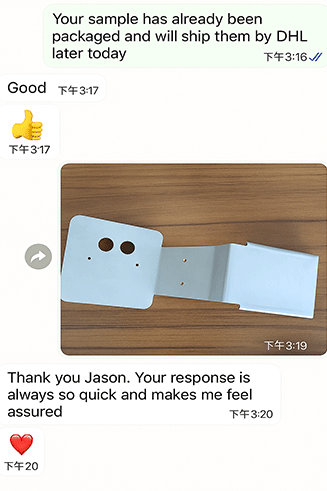

See What Customer Saying

Frequently asked questions

Do you provide samples? is it free or extra?

Yes, the sample fee depends on the product geometry, and the fee will be returned to your bulk order

How long can I get the sample?

Depends on your part, normally within 3-7 days

What shall we do if we do not have drawings?

Please send your sample to our factory, and then we can copy or provide you with better solutions. Please send us pictures or drafts with dimensions (Length, Height, Width), CAD or 3D file will be made for you if place orders

Will my drawings be safe after sending to you?

Yes, we can sign the NDA before getting your drawing and will not release it to the third party without your permission

What Material Types Can You Work With?

We work with a wide range of materials, including various grades of steel, stainless steel, aluminum, brass, copper, and more.

If I need urgent delivery, can you help?

Of course! Customer-first is our company philosophy. You need to tell us the delivery time when placing the order, and we will do our best to adjust the production schedule.